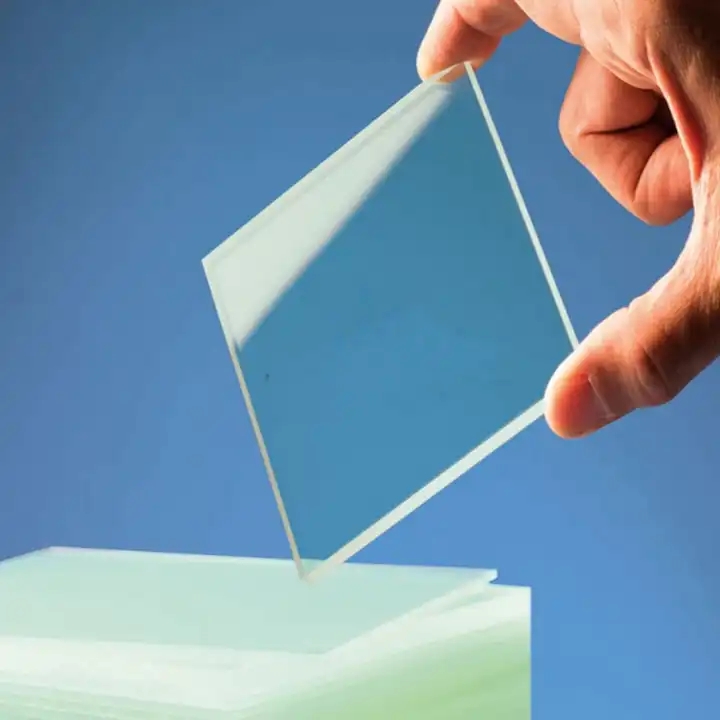

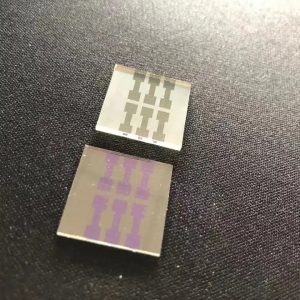

Description of the FTO Glass:

| Items: | FTO Coating glass for Lab |

| Optional Materials: | Low iron glass |

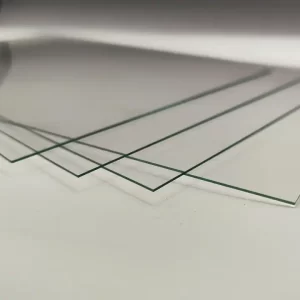

| Thickness: | 1.6mm, 2.2mm |

| Size: | 100*100*2.2mm, Customized size is available |

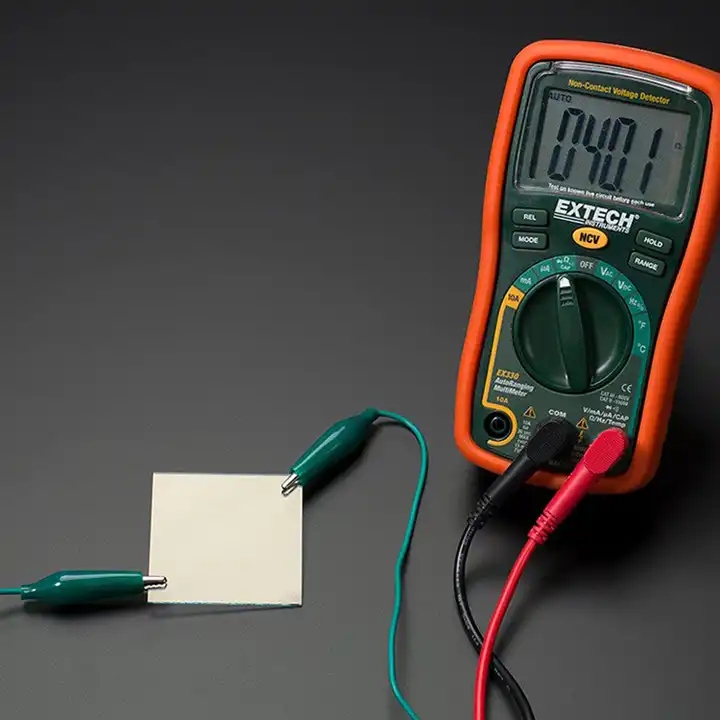

| Resistance Value | 15ohm/sqm |

| ITO Working temperature: | Up to 300 degrees centigrade |

| FTO Working temperature: | Up to 600 degrees centigrade |

| Production time: | 7-10 days for sample, 10-15 working days for mass production |

Here are some key features and uses of ITO glass in laboratory settings:

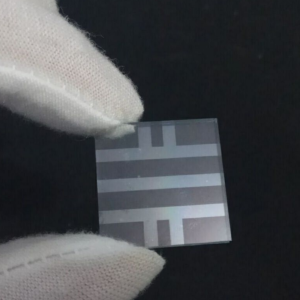

FTO conductive glass is a fluorine doped tin oxide SnO2 transparent conductive glass (SnO2: F), abbreviated as FTO. FTO glass has been developed and utilized as a replacement for ITO conductive glass, widely used in fields such as liquid crystal displays, catalysis, thin film solar cell substrates, dye sensitized solar cells, electrochromic glass, etc.

- ITO conductive glass is mainly produced by coating a transparent tin oxide (ITO) film on the glass using magnetron sputtering method. It is widely used in flat panel display devices, solar cells, and other optoelectronic devices. With the continuous updating and upgrading of flat panel display devices, it has a broader market space.

- Our company has various processes such as steam plating and electroplating, and supports the processing of ITO/FTO conductive glass, gold plating, silver plating, copper/molybdenum plating, and other coatings.

Reviews

There are no reviews yet.